Double-spiral batch mixers.

Double-spiral batch mixers are used for the preparation of homogenious mixtures from dry powdered and granulated mineral materials such as fertiliers, rubber derivatives; biological materials such as spices, and others such as polymers, bentonit. They can also be used for the averaging of the composition of batches of materials.

Mixer 4C11 ( volume 600 dm3 ) is used for mixing of suspensions, emulsions, and solutions.

Prerequisites for the components for dry mixtures: particles' size of up to 10 mm, content of moisture of up to 5 %, for liquid materials viscosity of up to 100 cSt.

The central part of the mixer consists of single- or double spirals, placed on a vertical shaft which rotates.

The components are loaded into the mixer in order to achieve a homogeneous composition of the mixture. The material if offloaded from the mixer and the process may be repeated on another batch of material.

The non-uniformity of prepared mixtures does not exceed 2 - 3 %.

Mixing time up to 10-20 min.

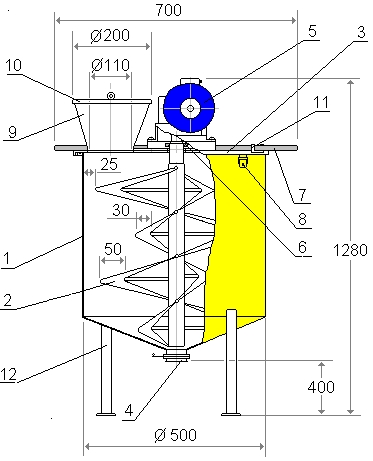

| 10С3 | 4C8 / 4C13 | 10C2 | |

| Volume of mixer, dm3 | 100 | 200 | 1200 |

| Power of electric motor, kW | 0,75 | 1,1 or 1,5 | 7,5 |

| Speed of working body rotation, rpm | 35 | 50 / 24 | 30-40 |

| Number of spirals | 1-2 | 1-2 | 2 |

| Max. dimensions, mm: | |||

| - diameter of mixing chamber | 500 | 600 | 1370 |

| - height | 1310 | 1700 | 2450 |

| Max. weight, kg | 85 | 150 | 450 |

| Sound level (at distance 1 m), dB | 45 | 50 | 70 |

Mixer 10C3

1. Housing 2. Spiral 3., 10. Cover 4. Slader

5. Motor 6. Reductor 7. Handles 8, 11. Fixator

9. Feeding funnel 12. Frame

Pictures: